Polypropylene, commonly referred to as PP, is a particularly common thermoplastic found in many places. Whether it is a bag, a car part, or a medical device used in a hospital, you can find this material. PP is so popular mainly because it offers several advantages, including resistance to chemical corrosion, durability, and economic viability.

Is Polypropylene Waterproof?

In fact, polypropylene can be waterproof. This is because its chemical structure is special; PP is a non-polar polymer with very high crystallinity, making it difficult for water molecules to pass through. The polymer chains inside PP are arranged very tightly, like a wall to keep the water out. Unlike materials that easily absorb water, PP is essentially water-resistant, with a water absorption rate of typically less than 0.01%. This makes it particularly suitable for use in the packaging industry.

Applications of Polypropylene

- Packaging

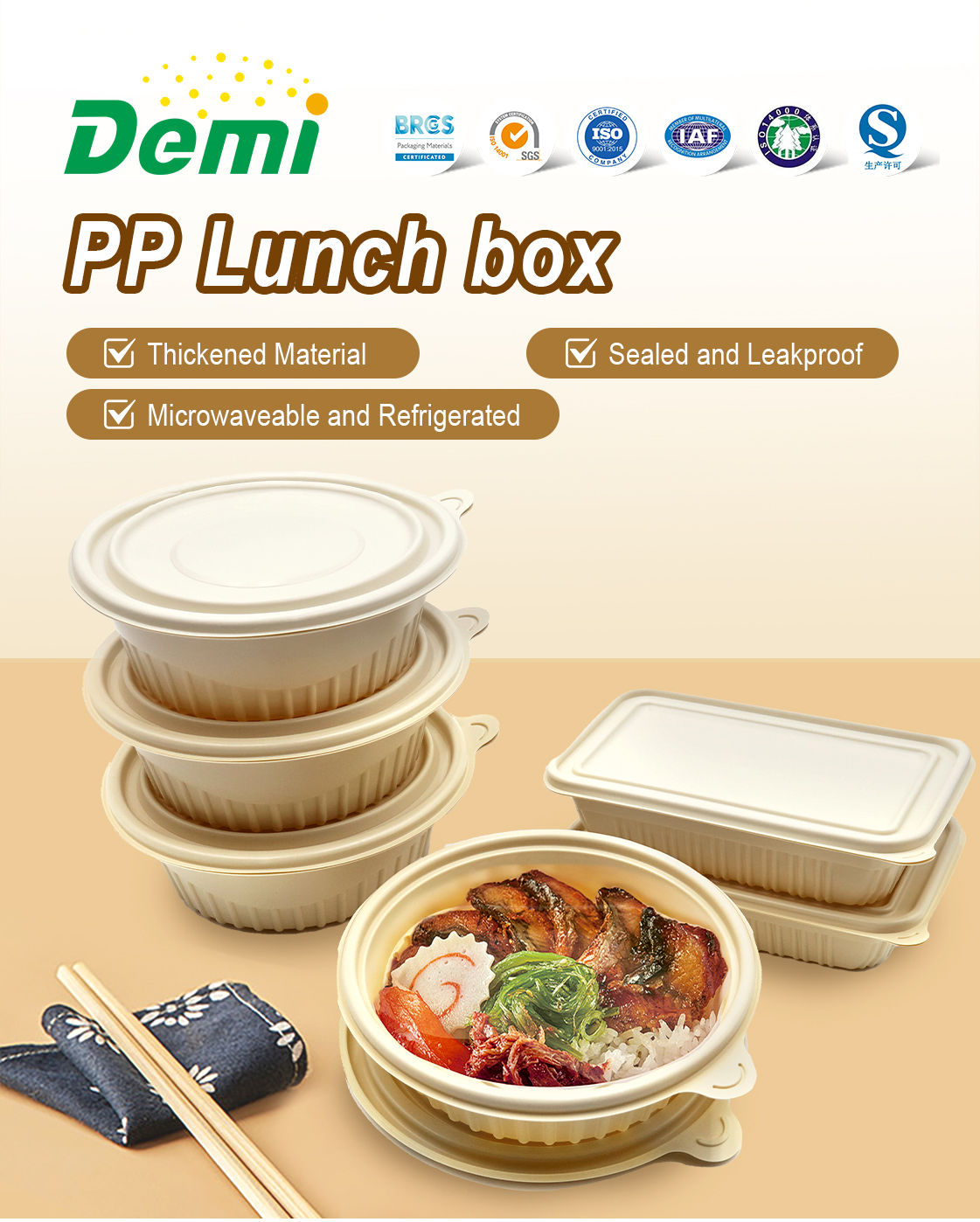

Polypropylene is particularly used in the packaging industry, mainly because it is waterproof, which helps meet food safety standards. Many of the food containers, caps, and plastic wraps we usually see are made of polypropylene. Among them, food trays and bento boxes are arguably one of the most important uses of polypropylene. Pallets are reasonably designed in different sizes, which can hold various types of food and are strong. These trays are very moisture-proof, which helps keep the food fresh and prevents contamination.

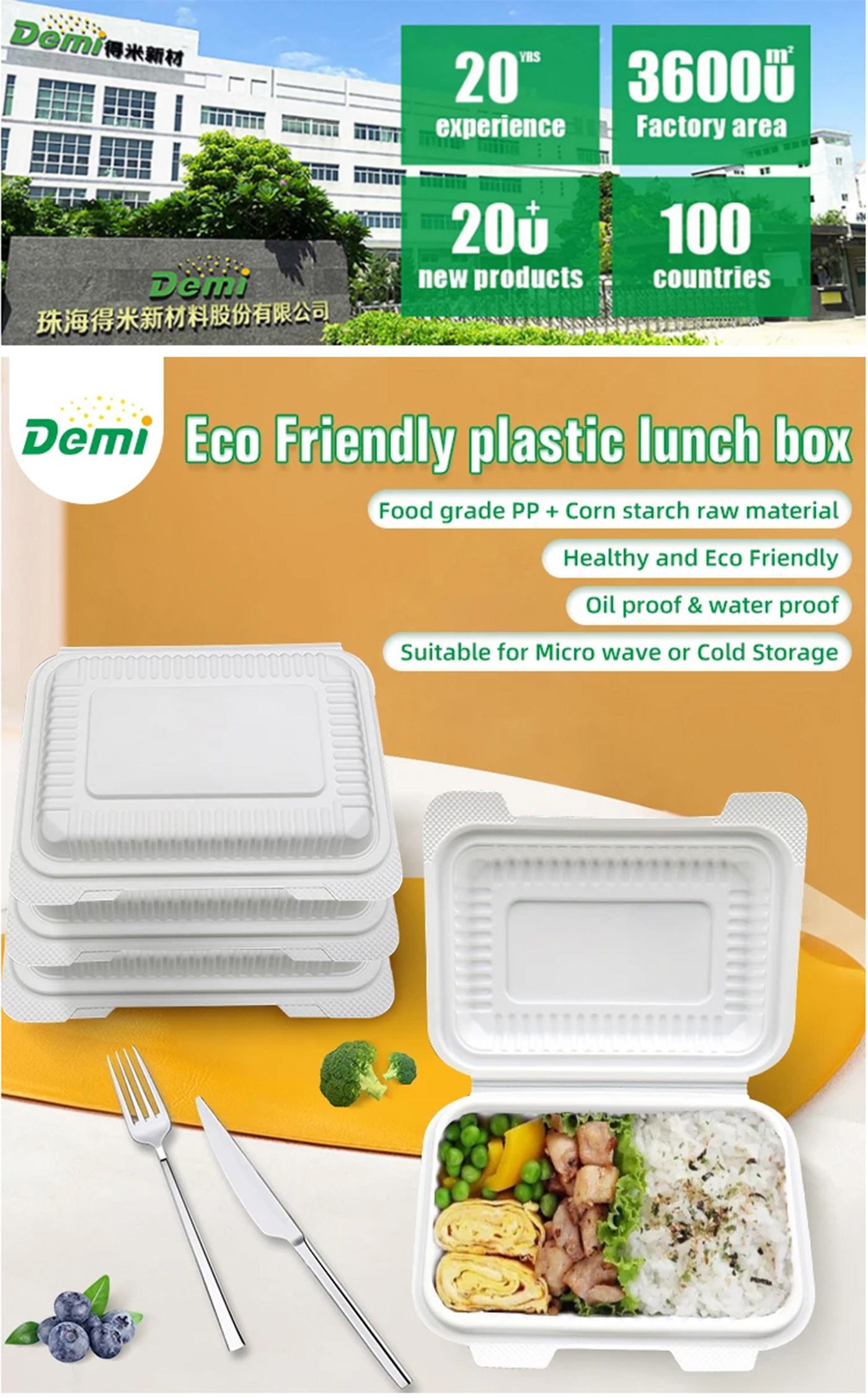

If you are looking for eco-friendly disposable PP lunch boxes, which ensure that meals are safely stored and transported without compromising on sustainability, please feel free to contact Demi, a lunch box manufacturer, who can also customize pallets of different sizes, thicknesses, and colors according to customer needs, and the fast delivery price is not expensive.

- Automotive Parts

In the automotive manufacturing industry, polypropylene is widely used due to its exceptional strength and resistance to corrosion from various chemicals. Now, many car dashboards, bumpers, and those decorative parts in the car, and even some less conspicuous lower parts, are made of polypropylene. This material is good, and its price is not too expensive, which is why car manufacturers like to use it to make a variety of accessories.

- Textiles

Polypropylene fiber has many uses in daily life, and we often see it made into things such as carpets, ropes, and sportswear. The biggest feature of this fiber is its lightweight and water-resistant properties, making it very suitable for clothes and various home items used during sports.

- Medical Devices

In the medical industry, PP materials are widely used to make disposable syringes, dishes, and various equipment used in the laboratory. This is mainly because bacteria do not easily contaminate PP materials themselves; they have strong resistance to chemicals, and can withstand the sterilization process of high-temperature disinfection.

- Consumer Goods

PP is also very common in our daily life, as seen in toys, furniture, and household appliances. This material is particularly safe and durable, making it resistant to damage. Its price is reasonable, which is why many people who need to use it for a long time, such as those who wear it daily, choose to use it.

- Industrial Products

For industrial applications, polypropylene is used in pipes, chemical tanks, and pallets due to its excellent corrosion-resistant properties and environmental stability.

Is Polypropylene Heat Resistant?

Polypropylene’s melting point can reach 160 degrees Celsius (320 degrees Fahrenheit). When the temperature rises to about 110 degrees Celsius, the PP material will begin to soften; the temperature is equivalent to 230 degrees Fahrenheit. When using PP material, it is best not to exceed 82 degrees Celsius (180 degrees Fahrenheit) to ensure normal operation. Even at temperatures as low as minus 20 degrees or minus 4 degrees Fahrenheit, it retains its original appearance and is resistant to breakage. This makes it suitable for both hot and ice foods.

PP material itself has many advantages, which make it particularly suitable for making environmentally friendly lunch boxes. Demi’s food-grade PP lunch boxes can be heated directly in the microwave oven. They can also be stored in the refrigerator or freezer without any issues. The leak-proof design ensures safety, and the boxes come in various sizes to suit different needs. Demi has been working in this industry for over 20 years, enabling them to quickly send goods worldwide at a particularly cost-effective price. As a result, many people prefer to buy their products for packing food.

Conclusion

Polypropylene (PP) is a non-polar polymer with high crystallinity. The molecular structure of this material is arranged particularly closely, just like a box that stuff is tightly packed, and the water is not drilled at all, so it is naturally has good waterproof performance. The experimental data show that the water absorption rate of PP is less than 0.01%, so the low water absorption rate makes it particularly suitable for food packaging, so that it can be used for food packaging, which can be very good at blocking water vapor.

Demi has been making polypropylene food trays and polypropylene lunch boxes since 2003 and has more than 20 years of experience, and can see their products in more than 100 countries around the world. They employ more than 200 workers in the factory, and 80 production lines are dedicated to producing these food trays, which can be customized according to customer needs and fully meet the international food safety requirements.

Demi products have received many patents and certifications, and many distributors like to cooperate with them, because we have a large production speed and stable quality. At the same time, it can also meet the food safety regulations of various countries. It is precisely because they insist on doing good products, so many companies look for both reliable and affordable food packaging, the first thing that comes to mind is Demi.